Cessna hand controls

Fall 2020

I am currently pursuing my Private Pilot’s License, training in Cessna’s 150/172.

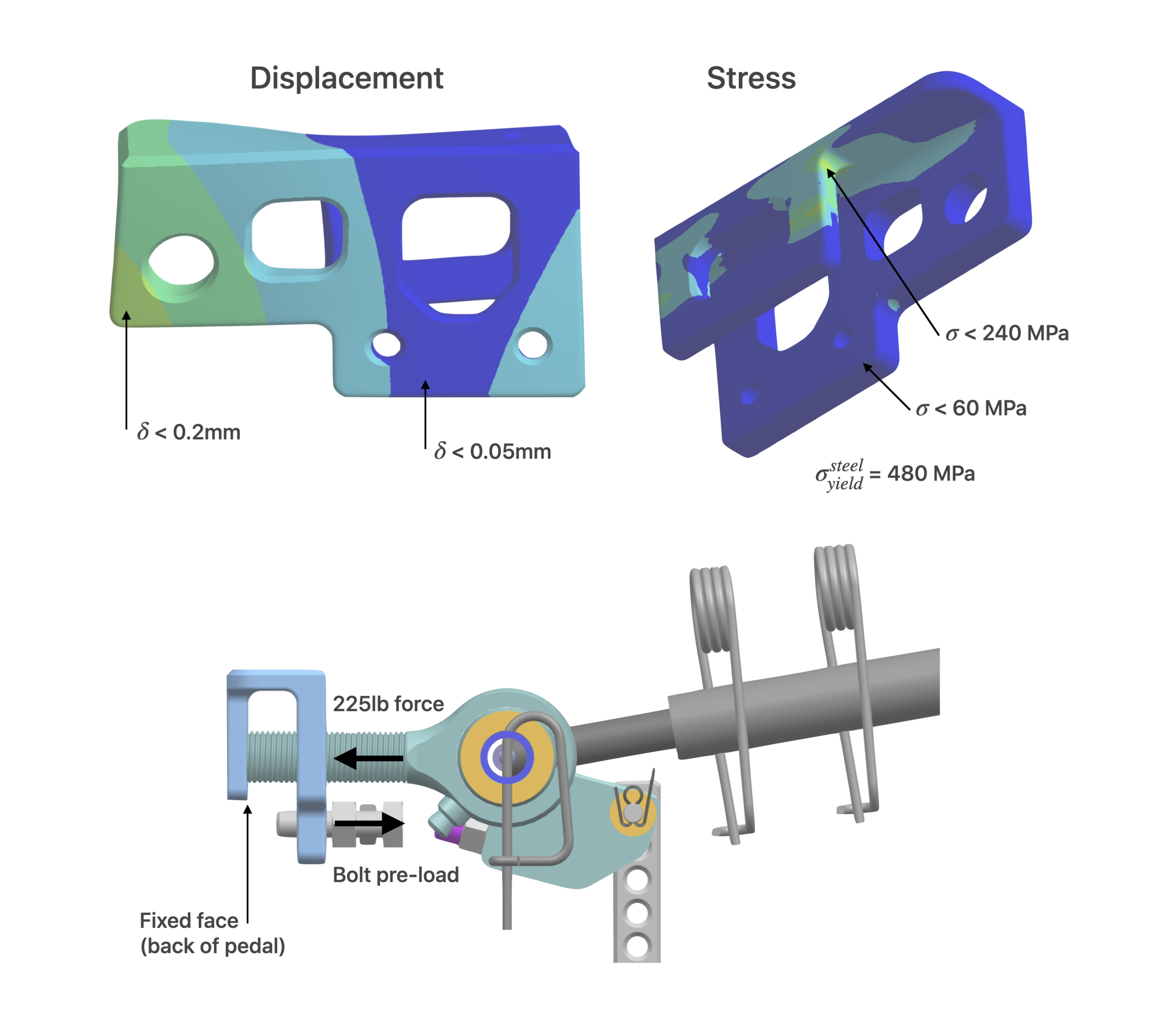

I require hand controls to work the rudder pedals, so building off a rough CAD of the Union Hand Controls designed in the 1970s, I redesigned the setup for modern CNC machining, preserving the materials and some weld joints in order to (hopefully) facilitate FAA re-approval.

Stress analysis of the part shows that even with the mechanical advantage of the long lever, my 50lbf press on the end still results in a minimum safety factor of ~4 (the 240MPa is mostly a mesh artifact).

Attachment to rudder pedals – an original model.

ASSEMBLY & PROTOTYPES

December 2020

This has been an exercise in designing for unknowns, since I don’t have a spec for force or translation required for full braking, the pedal geometry is similar but not exactly the same across multiple planes, and the pedal-well is hard to access for exact measurement!

To work with this uncertainty, I printed fixtures for handle and J-blocks to test positioning. When I was ready to begin welding, I printed a fixture for holding the T-joint, which you can see in-action below.

This was my first time TIG welding, and with Jared’s help and guidance, I loved how controllable the weld lines were.

3D printed mounts for testing sizing in the plane before welding.

My 3D printed fixture functioned exactly as intended!

Sights from the sky…

Over Northern Massachusetts

Over Aquatic Park, SF